Enhance Systems with Precision Hydraulic Control

- Hilton Van Rooyen

- Oct 2, 2025

- 4 min read

Hydraulic systems are the backbone of many industrial and business operations. Their efficiency and reliability directly impact productivity and operational costs. To ensure these systems perform at their best, it is essential to focus on control mechanisms that offer accuracy and responsiveness. This is where precision hydraulic control plays a pivotal role. By integrating advanced control solutions, businesses can enhance system performance, reduce downtime, and extend equipment lifespan.

Understanding the Importance of Precision Hydraulic Control

Hydraulic machinery relies on fluid power to perform tasks ranging from lifting heavy loads to operating complex manufacturing equipment. The control of this fluid power must be exact to avoid inefficiencies and potential damage. Precision hydraulic control ensures that the flow, pressure, and direction of hydraulic fluid are managed with high accuracy.

This level of control translates into smoother operation, better energy efficiency, and improved safety. For example, in a manufacturing plant, precise control of hydraulic presses can lead to consistent product quality and reduced material waste. Similarly, in construction equipment, it allows for delicate movements that prevent structural damage and enhance operator safety.

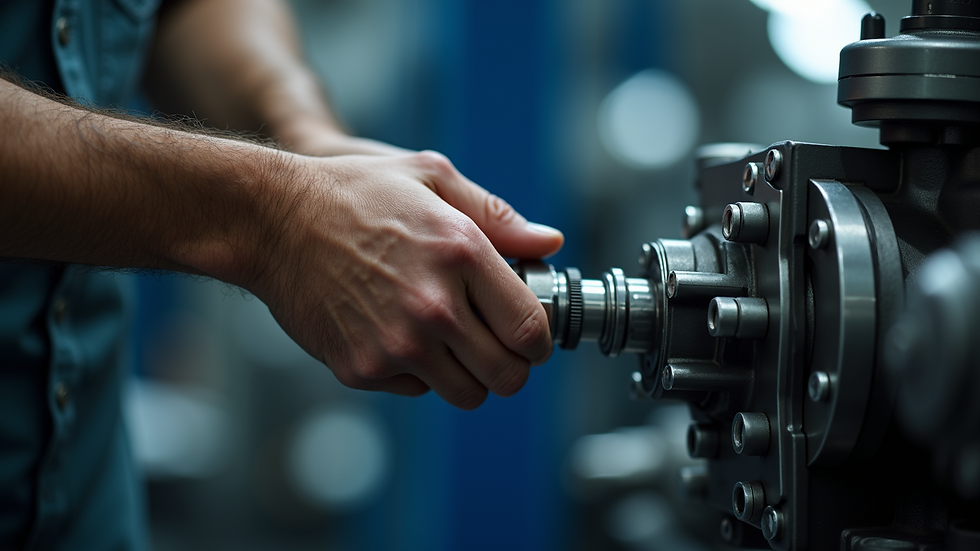

Hydraulic valve assembly ensuring accurate fluid control

Key Components That Enable Precision Hydraulic Control

Achieving precision in hydraulic systems depends on several critical components working in harmony. Understanding these parts helps in selecting the right equipment and maintaining optimal system performance.

Hydraulic Valves: These regulate the flow and pressure of the hydraulic fluid. Directional control valves, pressure relief valves, and flow control valves each serve specific functions to maintain system balance.

Actuators: Hydraulic cylinders and motors convert fluid power into mechanical motion. Their responsiveness depends on the control signals they receive.

Sensors and Feedback Devices: Modern systems use sensors to monitor pressure, flow rate, and position. Feedback from these sensors allows for real-time adjustments.

Control Units: Electronic or electro-hydraulic controllers process sensor data and adjust valve positions accordingly to maintain desired performance.

Regular inspection and maintenance of these components are crucial. For instance, worn seals in valves can cause leaks, reducing control accuracy and system efficiency. Replacing or repairing such parts promptly ensures the system remains reliable.

Industrial hydraulic system components arranged for maintenance

How to Adjust a Hydraulic Control Valve?

Adjusting a hydraulic control valve is a fundamental skill for maintaining system precision. Proper adjustment ensures the valve responds correctly to control inputs, maintaining the desired pressure and flow.

Identify the Valve Type: Different valves require different adjustment methods. Consult the manufacturer’s manual for specific instructions.

Prepare the System: Ensure the hydraulic system is depressurized and the machinery is safely shut down before making adjustments.

Locate the Adjustment Screw or Knob: Most valves have a clearly marked adjustment point.

Make Incremental Adjustments: Turn the screw or knob slowly while monitoring system pressure and flow. Use a pressure gauge or flow meter for accuracy.

Test the System: After adjustment, operate the machinery under normal conditions to verify performance.

Document Settings: Record the final adjustment settings for future reference and maintenance.

Incorrect adjustments can lead to system inefficiencies or damage. If unsure, it is advisable to consult with hydraulic system experts or service providers.

Technician carefully adjusting hydraulic valve settings

Benefits of Implementing Advanced Hydraulic Control Solutions

Integrating advanced hydraulic control solutions offers numerous advantages that directly impact operational success.

Enhanced Accuracy: Precise control reduces errors in machine operation, leading to higher product quality.

Improved Efficiency: Optimized fluid flow and pressure reduce energy consumption and wear on components.

Increased Safety: Controlled movements prevent accidents and equipment damage.

Reduced Downtime: Reliable control systems minimize unexpected failures and maintenance needs.

Extended Equipment Life: Proper control reduces stress on hydraulic components, prolonging their service life.

Businesses that invest in modern control technologies often see a significant return on investment through lower operational costs and improved output.

Partnering with Experts for Reliable Hydraulic System Performance

Maintaining and upgrading hydraulic systems requires specialized knowledge and experience. Partnering with a trusted service provider ensures that your equipment receives expert care tailored to your operational needs.

At PEX Hydraulic Repairs, we focus on delivering comprehensive solutions that keep your hydraulic machinery running smoothly. Our services include expert repair, replacement, and supply of hydraulic components. We understand the critical role of precision hydraulic control in system performance and work diligently to implement the best solutions for your business.

By choosing a reliable partner, you gain access to:

Skilled technicians with extensive hydraulic expertise

Quality parts and components sourced from reputable manufacturers

Timely service that minimizes operational disruptions

Customized maintenance plans to suit your equipment and usage patterns

Investing in professional support is a proactive step toward maximizing the efficiency and reliability of your hydraulic systems.

Enhancing your hydraulic systems with precise control mechanisms is not just a technical upgrade - it is a strategic move that safeguards your operations and boosts productivity. By understanding the components, mastering valve adjustments, and partnering with experts, you can ensure your hydraulic machinery performs at its peak. Embrace precision hydraulic control today and experience the difference it makes in your business.

Comments